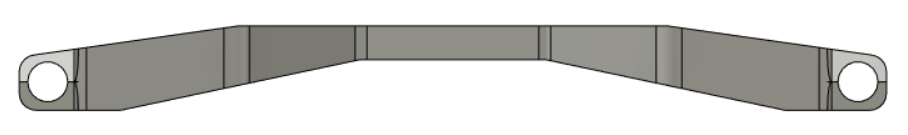

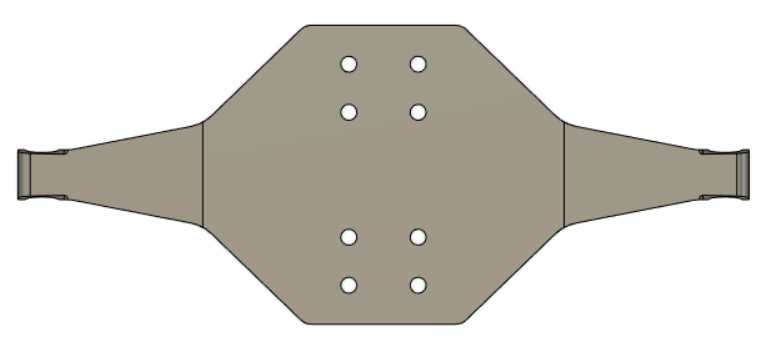

Trolley Bracket

A custom bracket was required to adapt industry standard Webb trolly bracket running on S4 I-beam rails to the W8 I-beam being used on our in-house design/built crane. After iterating the design and achieving a factor of safety greater than 5.0 at ultimate strength, the design was released for machining. Beginning with a 2.5” thick A36 plate steel rough cut to a +.25” condition the part went through four setups before being sent out for black oxide. Spherical bearings were pressed in to accommodate minor misalignment in the rails as the gantry moves through the shop.

Some unique challenges this part gave were significant material removal (stock @ 109.5lbs - final @ 26.5 lbs = 83 lbs removed) along with precision bored holes for bearing press fit. Web thickness was within +/- .003” of the design and the bearing bores were within 0.0004” diametrically.

Rough Stock with Clamping Dovetail

Clamping Dovetail Detail

1" Dia Sandvik 490 Roughing Complete

1" Roughing Complete

Profile Roughing Sandvik 390

Profile Roughing Complete

.75" Roughing Complete

.75" Roughing Complete

.75" Roughing Complete

.75" Roughing Complete

.375" Roughing Complete

.75" Ball Mill Stitching

.375" Ball Mill Finishing

Edge Break Complete

Op1 Complete

Op1 Complete

Op1 Complete

Op2 Setup For Spherical Bearing Boring

Verification Boring Alignment

Boring Complete for Spherical Bearing Press Fit

Op2 Complete

Op3 Verifying Alignment

.75 Ball Mill Stitching Complete

Edge Break Complete

Op3 Complete

Repeat two more times....

Back from Black Oxide

Spherical Bearing Install Complete

Finished!